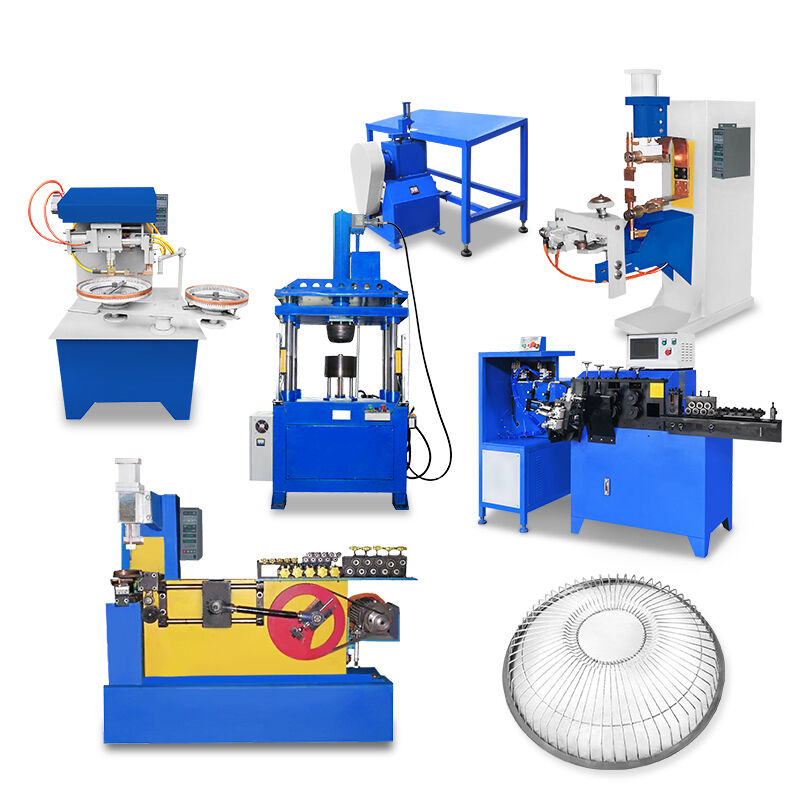

HWASHI फैन गार्ड उत्पादन लाइन का संपूर्ण उपकरण

हमारी पूरी तरह से एकीकृत फैन गार्ड विनिर्माण उत्पादन लाइन टिकाऊ, सटीक-इंजीनियर फैन गार्ड के उच्च-मात्रा उत्पादन के लिए एंड-टू-एंड स्वचालन प्रदान करती है। रोबोटिक सिस्टम, सीएनसी-सक्षम टूलिंग और एआई-संचालित गुणवत्ता नियंत्रण का संयोजन, यह टर्नकी समाधान औद्योगिक, एचवीएसी और उपभोक्ता उपकरण अनुप्रयोगों के लिए वायर ग्रिल्स, मेश स्क्रीन और स्टैम्प्ड मेटल गार्ड के निर्माण को सुव्यवस्थित करता है।

स्वचालित वायर रिंग मेकिंग और बट वेल्डिंग मशीन

यह उपकरण लोहे की रिंगों के स्वचालित उत्पादन में विशेषज्ञता रखता है। जब लोहे का तार उपकरण द्वारा निर्धारित छेद की स्थिति में प्रवेश करता है, तो यह पहले से निर्धारित परिधि मान, मात्रा विनिर्देशों और लाइन गति मापदंडों के आधार पर स्वचालित रूप से संचालन शुरू कर देता है।

रिंग मशीन का नमूना प्रभाव

इनर रिंग के लिए स्वचालित स्पॉट वेल्डर

यह उपकरण फैन गार्ड की इनर रिंगों की वेल्डिंग के लिए उपयोग किया जाता है। इसमें पहले से निर्धारित तार मात्रा और लंबाई मापदंडों के आधार पर स्वचालित तार फीडिंग, स्वचालित तार कटिंग और स्वचालित रोटरी वेल्डिंग क्षमताएं हैं।

वेल्डिंग हेड

स्वचालित मिडिल रिंग वेल्डिंग मशीन

यह मशीन विशेष रूप से फैन गार्ड के मिडिल रिंग घटकों की वेल्डिंग के लिए डिज़ाइन की गई है।

वेल्डिंग हेड

स्वचालित आउटर रिंग वेल्डिंग मशीन

यह उपकरण फैन गार्ड की आउटर रिंग की वेल्डिंग के लिए उपयोग किया जाता है। वेल्डेड इनर रिंग और आउटर रिंग घटकों को सटीक असेंबली के लिए मोल्ड पर रखा जाता है।

वेल्डिंग हेड

25T हाइड्रोलिक प्रेस मशीन

यह उपकरण फैन गार्ड के इनर रिंगों के हाइड्रोलिक बनाने के लिए उपयोग किया जाता है।

हाइड्रोलिक बनाने वाले मोल्ड

एज ट्रिमिंग मशीन

यह उपकरण तेज कटिंग गति और चिकनी सतह परिष्करण के साथ फैन गार्ड को ट्रिम करने के लिए उपयोग किया जाता है।

ट्रिमिंग के बाद का प्रभाव सपाट है

मशीन का विवरण

| विशिष्टता |

मूल्य |

| रेटेड क्षमता |

10-300KVA |

| अधिकतम वेल्डिंग मोटाई |

900mm × 1150mm × 1750mm |

| आयाम |

900mm × 1150mm × 1750mm |

| वज़न |

450 KG |

अनुप्रयोग और नमूने

हम आपके लिए अनुकूलित सेवा प्रदान कर सकते हैं। हमारे इंजीनियर आपके साथ विशिष्ट वेल्डिंग आवश्यकताओं पर चर्चा करेंगे और आपके नमूनों या चित्रों के आधार पर उपयुक्त तकनीकी प्रस्ताव विकसित करेंगे।

फैक्टरी और प्रमाणपत्र

प्रमाणपत्र

हमने सहित अंतर्राष्ट्रीय प्रमाणपत्र पारित किए हैं CE प्रमाणन, ISO9001 गुणवत्ता प्रबंधन प्रणाली प्रमाणन, अलीबाबा उद्यम प्रमाणन, और डिज़ाइन पेटेंट।

बिक्री के बाद सेवा और ग्राहक सहायता

- स्पॉट वेल्डिंग मशीन 1 साल की वारंटी उपभोज्य भागों को छोड़कर

- बहुत अधिक तकनीकी सहायता ऑनलाइन उपलब्ध है

- त्वरित बैकअप पार्ट्स उपलब्ध और तकनीकी सहायता

- प्रशिक्षण वीडियो, निर्देश पुस्तिका और संचालन मैनुअल प्रदान किया गया

सेवा टीम और ग्राहक प्रतिक्रिया

पेशेवर टीम

इन वर्षों में, Hwashi ने बड़ी संख्या में प्रतिभाशाली, समर्पित और अभिनव पेशेवरों को विकसित किया है। हमारे पास विद्युत इंजीनियरिंग, यांत्रिक डिजाइन और वेल्डिंग प्रौद्योगिकी में व्यापक अनुभव वाले विशेषज्ञों की एक विशेष टीम है।

अपनी स्थापना के बाद से 22 साल पहले, HWASHI टेक्नोलॉजी ने दुनिया भर में यात्रा की है, 100 से अधिक प्रदर्शनियों में भाग लिया है, और 8,000 से अधिक ग्राहकों की सेवा की है।

अक्सर पूछे जाने वाले प्रश्न

Q1: आपकी मशीन की कीमत क्या है?

हमारी मशीनें आपकी विशिष्ट आवश्यकताओं के लिए अनुकूलित हैं। एक उचित मूल्य उद्धरण प्राप्त करने के लिए, कृपया हमें निम्नलिखित जानकारी प्रदान करें:

- आपके उत्पाद की सामग्री और मोटाई

- आपके उत्पाद का न्यूनतम और अधिकतम आकार

- आपके उत्पादों की वेल्डिंग स्थिति

- आप जिस स्वचालन स्तर को प्राप्त करना चाहते हैं

- विस्तृत उत्पाद चित्र प्रदान करने से हमारे इंजीनियरों को उपयुक्त तकनीकी प्रस्ताव और मूल्य निर्धारण विकसित करने की अनुमति मिलती है।

Q2: आपकी मशीन की वारंटी अवधि क्या है?

हमारी मानक वारंटी अवधि शिपमेंट के बाद एक वर्ष है। विस्तारित वारंटी अवधि अतिरिक्त लागत पर उपलब्ध हैं।

Q3: यदि वारंटी अवधि के दौरान मेरी मशीन क्षतिग्रस्त हो जाती है तो क्या होगा?

हमारे इंजीनियर पहले ऑनलाइन मार्गदर्शन के माध्यम से समस्या का निदान करने में मदद करेंगे। यदि वारंटी अवधि के दौरान कोई भी भाग क्षतिग्रस्त हो जाता है, तो हम मुफ्त में प्रतिस्थापन भाग भेजेंगे। यदि भाग प्रतिस्थापन के बाद भी समस्या बनी रहती है, तो हम समस्या को हल करने के लिए आपके कारखाने में एक इंजीनियर भेजेंगे।

Q4: आपकी मशीन का डिलीवरी समय क्या है?

डिलीवरी का समय मशीन की जटिलता पर निर्भर करता है। अधिकांश मानक मशीनें स्टॉक में हैं और भुगतान के सात दिनों के भीतर शिप की जा सकती हैं। अनुकूलित मशीनों को पूरा होने में आमतौर पर 30-90 दिन लगते हैं।

Q5: क्या हम वेल्डिंग परीक्षणों के लिए आपको नमूने भेज सकते हैं?

हाँ। आप हमें वेल्डिंग परीक्षणों के लिए नमूने भेज सकते हैं, और हम परिणामों की तस्वीरें और वीडियो प्रदान करेंगे। यदि आवश्यक हो, तो हम ऑर्डर देने से पहले गुणवत्ता सत्यापन के लिए परीक्षण किए गए नमूनों को आपके देश में वापस कर सकते हैं।

Q6: क्या आप मशीन चित्र और तकनीकी प्रस्ताव प्रदान कर सकते हैं?

हाँ। आपकी विस्तृत आवश्यकताओं और उत्पाद चित्रों को प्राप्त करने के बाद, हमारे इंजीनियर बुनियादी मशीन अवधारणा चित्रों के साथ उपयुक्त तकनीकी प्रस्ताव विकसित करेंगे। ऑर्डर देने के बाद, हम निर्माण शुरू होने से पहले पुष्टि के लिए विस्तृत डिज़ाइन चित्र प्रदान करते हैं।

Q7: आपके भुगतान की शर्तें क्या हैं?

हम टी/टी, एल/सी, वेस्टर्न यूनियन और अलीबाबा ट्रेड एश्योरेंस स्वीकार करते हैं। हम अलीबाबा ट्रेड एश्योरेंस की अनुशंसा करते हैं, जो विलंबित शिपिंग या मशीन असंतोष के लिए शिकायतें करने की अनुमति देता है।

Q8: हम मशीन कैसे स्थापित कर सकते हैं?

सरल मशीनों के लिए, हम अंग्रेजी संचालन मैनुअल, संचालन वीडियो और ऑनलाइन मार्गदर्शन/प्रशिक्षण प्रदान करते हैं। जटिल मशीनों के लिए, हम स्थापना और प्रशिक्षण के लिए इंजीनियर भेज सकते हैं, जिसमें संबंधित लागतें (वेतन, वीजा, यात्रा, आवास) खरीदार द्वारा वहन की जाती हैं।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!