उत्पाद का वर्णन:

स्वचालित तार शेल्फ वेल्डिंग मशीन एक अत्याधुनिक तार शेल्फ निर्माण मशीन है जिसे तार शेल्फ इकाइयों के उत्पादन में क्रांति लाने के लिए डिज़ाइन किया गया है।यह उन्नत मशीनरी बेजोड़ सटीकता प्रदान करती है, दक्षता, और स्वचालन, यह तार शेल्फ निर्माण में विशेषज्ञता निर्माताओं के लिए एक अनिवार्य उपकरण बना रहा है।और विभिन्न उद्योगों में सौंदर्य के अनुकूल तार रैक, यह स्वचालित तार रैक वेल्डर एक शीर्ष स्तरीय समाधान के रूप में खड़ा है जो पूरे निर्माण प्रक्रिया को सुव्यवस्थित करता है।

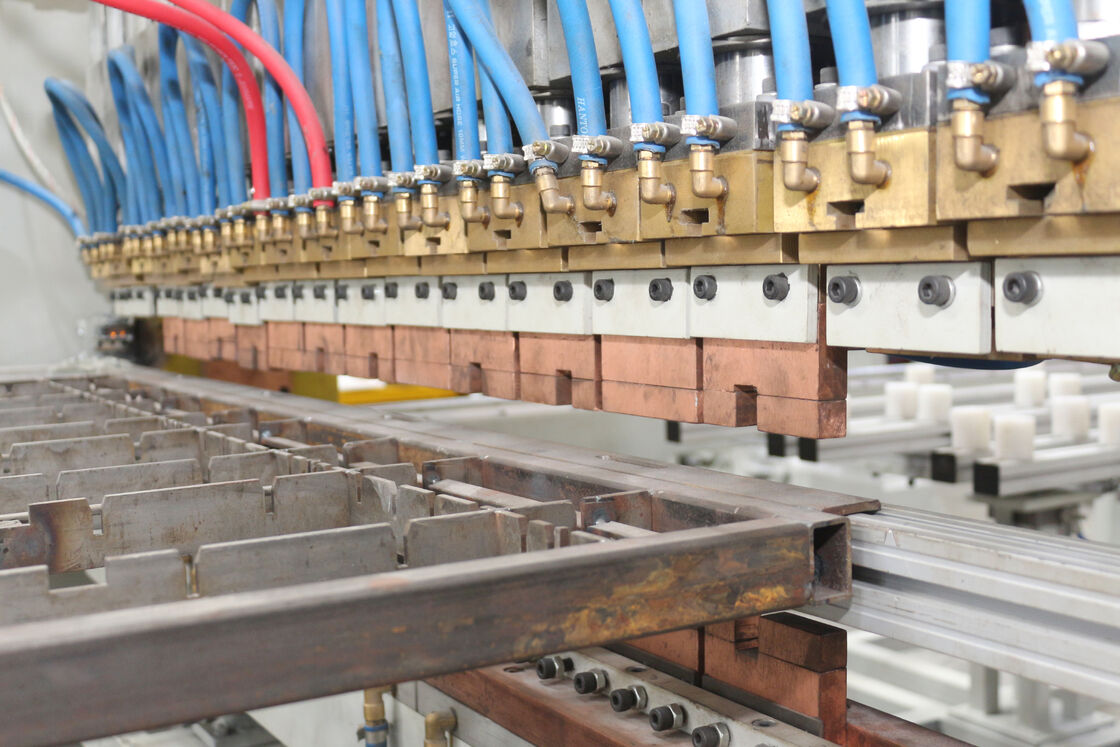

इसके मूल में, स्वचालित तार शेल्फ वेल्डिंग मशीन तार शेल्फ पर सुसंगत, उच्च गुणवत्ता वाले वेल्ड प्रदान करने के लिए बुद्धिमान नियंत्रण प्रणालियों के साथ अत्याधुनिक वेल्डिंग तकनीक को एकीकृत करती है।मशीन तार के आकार और विन्यास की एक विस्तृत श्रृंखला को संभालने के लिए इंजीनियर है, विभिन्न उत्पादन आवश्यकताओं के लिए बहुमुखी प्रतिभा और अनुकूलन क्षमता सुनिश्चित करता है।यह मशीन सटीक वेल्डिंग जोड़ों के माध्यम से मजबूत संरचनात्मक अखंडता की गारंटी देता है.

इस वायर शेल्फ फैब्रिकेशन मशीन के मुख्य लाभों में से एक इसका पूरी तरह से स्वचालित संचालन है। स्वचालित वायर रैक वेल्डर मैन्युअल हस्तक्षेप की आवश्यकता को काफी कम करता है,जो न केवल श्रम लागत को कम करता है बल्कि सुरक्षा और उत्पादकता में भी वृद्धि करता हैऑपरेटर आसानी से पैरामीटर सेट कर सकते हैं और सहज उपयोगकर्ता इंटरफ़ेस के माध्यम से वेल्डिंग प्रक्रिया की निगरानी कर सकते हैं, जिससे त्वरित समायोजन और वास्तविक समय गुणवत्ता नियंत्रण की अनुमति मिलती है।इस स्तर का स्वचालन यह सुनिश्चित करता है कि प्रत्येक तार शेल्फ सटीक विनिर्देशों के अनुसार निर्मित हो, सामग्री अपशिष्ट और पुनर्मिलन को कम करना।

स्थायित्व और विश्वसनीयता तार शेल्फ उत्पादन में सर्वोपरि हैं, और यह मशीन दोनों पहलुओं में उत्कृष्ट है। उच्च गुणवत्ता वाली सामग्री और घटकों से निर्मित,स्वचालित तार शेल्फ वेल्डिंग मशीन निरंतर औद्योगिक उपयोग का सामना करने के लिए बनाया गया हैइसकी मजबूत डिजाइन डाउनटाइम और रखरखाव आवश्यकताओं को कम करती है, जिससे निर्माताओं को गुणवत्ता पर समझौता किए बिना स्थिर उत्पादन दर बनाए रखने में सक्षम बनाता है।मशीन की ऊर्जा कुशल वेल्डिंग तकनीक बेहतर प्रदर्शन बनाए रखते हुए परिचालन लागत को कम करने में मदद करती है.

अनुकूलन इस तार शेल्फ निर्माण मशीन का एक और प्रमुख विशेषता है। यह विभिन्न वेल्डिंग पैटर्न और विन्यास का समर्थन करता है,निर्माताओं को ग्राहकों की विशिष्ट आवश्यकताओं के अनुरूप तार से बने अलमारियों का उत्पादन करने की अनुमतिचाहे वह तार ग्रिड की दूरी को समायोजित करना हो, शेल्फ आयामों को बदलना हो या विशेष सुविधाओं को शामिल करना हो, यह मशीन कस्टम वायर रैक निर्माण के लिए आवश्यक लचीलापन प्रदान करती है।यह अनुकूलनशीलता इसे उन व्यवसायों के लिए आदर्श बनाती है जो अपने उत्पाद प्रस्तावों का विस्तार करना चाहते हैं या आला बाजारों को पूरा करना चाहते हैं.

अपने उत्पादन लाइन में स्वचालित तार रैक वेल्डर को शामिल करने से बेहतर विनिर्माण क्षमताओं से परे कई लाभ मिलते हैं।सटीक वेल्डिंग प्रक्रिया स्वच्छ बनाकर तार अलमारियों की समग्र सौंदर्य अपील को बढ़ाती हैइसके अलावा मशीन की गति और दक्षता उच्च उत्पादन मात्राओं को सक्षम करती है।कंपनियों को बढ़ते बाजार की मांगों को पूरा करने और लीड समय को कम करने में मदद करना.

संक्षेप में, स्वचालित तार शेल्फ वेल्डिंग मशीन आधुनिक तार शेल्फ निर्माण की जरूरतों के लिए एक व्यापक समाधान है। स्वचालन, सटीकता, स्थायित्व और अनुकूलन को मिलाकर,यह निर्माताओं को उच्च गुणवत्ता वाले तार रैक का उत्पादन कुशलतापूर्वक और लागत प्रभावी ढंग से करने में सक्षम बनाता हैचाहे आप एक छोटी कार्यशाला हो या एक बड़े पैमाने पर उत्पादन सुविधा, इस वायर शेल्फ फैब्रिकेशन मशीन में निवेश करने से आपकी विनिर्माण प्रक्रिया और उत्पाद की गुणवत्ता नई ऊंचाइयों पर पहुंच जाएगी।इस उन्नत स्वचालित तार रैक वेल्डर के साथ तार शेल्फ उत्पादन के भविष्य का अनुभव करें और एक प्रतिस्पर्धी बाजार में आगे रहें.

विशेषताएं:

- उच्च परिशुद्धता और दक्षता के लिए उन्नत तार शेल्फ वेल्डिंग प्रणाली

- न्यूनतम मानव हस्तक्षेप के साथ पूर्ण स्वचालित संचालन

- निरंतर औद्योगिक उपयोग के लिए उपयुक्त टिकाऊ और मजबूत डिजाइन

- उत्पादकता बढ़ाने के लिए उच्च गति वाली वेल्डिंग प्रक्रिया

- आसान प्रोग्रामिंग और नियंत्रण के लिए उपयोगकर्ता के अनुकूल इंटरफ़ेस

- विभिन्न तार आकारों और शेल्फ डिजाइन के साथ संगत

- स्वचालित तार शेल्फ निर्माता जो निरंतर गुणवत्ता सुनिश्चित करता है

- परिचालन लागतों को कम करने के लिए ऊर्जा कुशल घटक

- ऑपरेटरों की सुरक्षा के लिए एकीकृत सुरक्षा सुविधाएँ

- विश्वसनीय प्रदर्शन के साथ कम रखरखाव आवश्यकताएं

- तार शेल्फ निर्माण मशीन अनुकूलित शेल्फ विन्यास का उत्पादन करने में सक्षम

- कारखाने के फर्श के स्थान को अनुकूलित करने के लिए कॉम्पैक्ट पदचिह्न

तकनीकी मापदंडः

| उत्पाद का नाम |

स्वचालित तार शेल्फ वेल्डर |

| मशीन का प्रकार |

तार शेल्फ विनिर्माण मशीन |

| वेल्डिंग विधि |

स्वचालित स्पॉट वेल्डिंग |

| तार व्यास सीमा |

2mm - 8mm |

| वेल्डिंग गति |

प्रति घंटे 600 वेल्ड तक |

| विद्युत आपूर्ति |

220V / 380V, 50/60Hz |

| मशीन के आयाम |

2500mm x 1500mm x 1600mm |

| वजन |

800 किलो |

| नियंत्रण प्रणाली |

टच स्क्रीन इंटरफेस के साथ पीएलसी |

| सामग्री संगतता |

कार्बन स्टील, स्टेनलेस स्टील |

अनुप्रयोग:

HWASHI स्वचालित वायर शेल्फ वेल्डिंग मशीन, मॉडल HS-HC-1-7 एक उन्नत समाधान है जिसे विशेष रूप से वायर शेल्फ उत्पादों के कुशल निर्माण के लिए डिज़ाइन किया गया है।यह अत्याधुनिक स्वचालित तार रैक वेल्डर तार रैक उत्पादन में उच्च परिशुद्धता और स्थिरता की आवश्यकता उद्योगों के लिए आदर्श हैसीई, सीसीसी और आईएसओ द्वारा प्रमाणित, यह विश्वसनीय प्रदर्शन और अंतरराष्ट्रीय गुणवत्ता मानकों के अनुपालन की गारंटी देता है।

चीन में डिजाइन और निर्मित, HWASHI HS-HC-1-7 विभिन्न अनुप्रयोग अवसरों और परिदृश्यों में उत्कृष्ट है।यह उन कारखानों के लिए एकदम उपयुक्त है जो वाणिज्यिक के लिए तार रैक और तार शेल्फिंग इकाइयों का उत्पादन करते हैं।चाहे आप एक छोटी कार्यशाला या एक बड़ी विनिर्माण सुविधा संचालित करते हैं,यह स्वचालित तार शेल्फ निर्माता तार रैक के वेल्डिंग स्वचालित करके उत्पादन प्रक्रिया को सुव्यवस्थित करता है, श्रम लागत में काफी कमी और उत्पादन दक्षता में वृद्धि।

विशिष्ट अनुप्रयोग परिदृश्यों में खुदरा डिस्प्ले, गोदाम भंडारण प्रणालियों और रसोई या अलमारी अलमारियों के समाधानों के लिए तार अलमारियों का बड़े पैमाने पर उत्पादन शामिल है।मशीन की सटीक वेल्डिंग क्षमता मजबूत सुनिश्चित करती है, समान वेल्ड, जो तार रैक की संरचनात्मक अखंडता और स्थायित्व के लिए महत्वपूर्ण हैं।इसका उपयोगकर्ता के अनुकूल इंटरफेस और मजबूत निर्माण इसे मांग वाले वातावरण में निरंतर संचालन के लिए उपयुक्त बनाता है.

प्रति माह 50 सेट की आपूर्ति क्षमता के साथ, HWASHI केवल एक सेट की न्यूनतम आदेश मात्रा के साथ छोटे और बड़े दोनों आदेशों को समायोजित कर सकता है।भुगतान प्राप्त होने के 7 से 30 कार्य दिवसों के बीच डिलीवरी का समयएल/सी और टी/टी जैसे भुगतान शर्तें सुचारू लेनदेन की सुविधा के लिए लचीले विकल्प प्रदान करती हैं।परिवहन के दौरान सुरक्षा के लिए मशीन को सुरक्षित रूप से समुद्र के अनुकूल लकड़ी के पैकेज में पैक किया जाता है, यह सुनिश्चित करने के लिए कि यह उत्कृष्ट स्थिति में पहुंचे।

संक्षेप में, HWASHI स्वचालित तार रैक वेल्डर HS-HC-1-7 तार रैक निर्माण में शामिल व्यवसायों के लिए एक विश्वसनीय और कुशल विकल्प है। इसकी उन्नत स्वचालन, गुणवत्ता प्रमाणपत्र,और लचीले खरीद विकल्पों इसे अपने तार अलमारियों विनिर्माण संचालन में उत्पादकता और उत्पाद की गुणवत्ता में वृद्धि के लिए एकदम सही भागीदार बनाते हैं.

सहायता एवं सेवाएं:

हमारे स्वचालित तार शेल्फ वेल्डिंग मशीन तार शेल्फ उत्पादन के लिए कुशल और विश्वसनीय वेल्डिंग समाधान प्रदान करने के लिए बनाया गया है।कृपया सुनिश्चित करें कि मशीन का संचालन उपयोगकर्ता पुस्तिका के अनुसार किया जाता है और अधिकतम प्रदर्शन सुनिश्चित करने के लिए नियमित रूप से रखरखाव किया जाता है.

हम स्थापना मार्गदर्शन, नियमित रखरखाव, समस्या निवारण सहायता और स्पेयर पार्ट्स की आपूर्ति सहित व्यापक सेवाएं प्रदान करते हैं।हमारी तकनीकी सहायता टीम आपकी वेल्डिंग मशीन की उत्पादकता और जीवन काल को अधिकतम करने में आपकी सहायता करने के लिए समर्पित है.

यदि आप ऑपरेशन के दौरान किसी भी समस्या का सामना करते हैं, तो कृपया सामान्य समस्याओं और समाधानों के लिए मैनुअल के समस्या निवारण अनुभाग को देखें। अधिक जटिल तकनीकी पूछताछ के लिए,हमारे सहायता विशेषज्ञ आपकी चिंताओं को शीघ्र हल करने के लिए विस्तृत सहायता प्रदान कर सकते हैं.

नियमित रखरखाव सेवाओं में सफाई, स्नेहन, विद्युत घटकों का निरीक्षण और वेल्डिंग सटीकता बनाए रखने के लिए कैलिब्रेशन शामिल हैं।हम अप्रत्याशित डाउनटाइम से बचने और लगातार वेल्ड गुणवत्ता सुनिश्चित करने के लिए आवधिक चेक-अप शेड्यूल करने की सलाह देते हैं.

समर्थन सेवाओं के अतिरिक्त, हम ऑपरेटर प्रशिक्षण कार्यक्रम प्रदान करते हैं ताकि आपके कर्मचारियों को स्वचालित वायर शेल्फ वेल्डिंग मशीन का सुरक्षित और प्रभावी ढंग से उपयोग करने में कुशल बनने में मदद मिल सके।

हमारी प्रतिबद्धता असाधारण ग्राहक सेवा प्रदान करना है और यह सुनिश्चित करना है कि आपके वेल्डिंग संचालन न्यूनतम व्यवधानों के साथ सुचारू रूप से चलें।

पैकिंग और शिपिंगः

उत्पाद का पैकेजिंग और शिपिंग

स्वचालित तार शेल्फ वेल्डिंग मशीन को सुरक्षित रूप से पैक किया गया है ताकि परिवहन के दौरान सुरक्षित वितरण और सुरक्षा सुनिश्चित हो सके।प्रत्येक इकाई को खरोंच और क्षति से बचाने के लिए फोम और प्लास्टिक की फिल्म जैसी सुरक्षात्मक सामग्री से सावधानीपूर्वक लपेटा जाता हैइसके बाद मशीन को एक मजबूत लकड़ी के डिब्बे या प्रबलित कार्डबोर्ड बॉक्स के अंदर रखा जाता है, जिसे कठोर हैंडलिंग और पर्यावरण कारकों का सामना करने के लिए डिज़ाइन किया गया है।

पैकेजिंग के आयाम और वजन को कुशल शिपिंग और हैंडलिंग की सुविधा के लिए अनुकूलित किया गया है।आसानी से पहचान के लिए पैकेजिंग के बाहरी हिस्से पर हैंडलिंग निर्देशों और उत्पाद विवरण के साथ स्पष्ट लेबलिंग लगाई जाती है.

शिपिंग के लिए, हम ग्राहक की आवश्यकताओं और गंतव्य के आधार पर समुद्री माल ढुलाई, हवाई माल ढुलाई और एक्सप्रेस कूरियर सेवाओं सहित कई विकल्प प्रदान करते हैं।सभी शिपमेंटों को ट्रैक किया जाता है और ग्राहक के निर्दिष्ट स्थान पर समय पर और सुरक्षित वितरण की गारंटी देने के लिए बीमा किया जाता है।.

शिपमेंट से पहले, प्रत्येक मशीन का गहन निरीक्षण और परीक्षण किया जाता है ताकि यह सुनिश्चित किया जा सके कि यह गुणवत्ता मानकों को पूरा करती है और आगमन पर ठीक से काम करती है।

अक्सर पूछे जाने वाले प्रश्न:

Q1: HWASHI HS-HC-1-7 स्वचालित तार शेल्फ वेल्डिंग मशीन के पास क्या प्रमाण पत्र हैं?

A1: HWASHI HS-HC-1-7 मॉडल CE, CCC और ISO मानकों के साथ प्रमाणित है, जो उच्च गुणवत्ता और सुरक्षा सुनिश्चित करता है।

Q2: इस वेल्डिंग मशीन के लिए न्यूनतम आदेश मात्रा क्या है?

A2: HWASHI HS-HC-1-7 स्वचालित वायर शेल्फ वेल्डिंग मशीन के लिए न्यूनतम आदेश मात्रा 1 सेट है।

Q3: इस मशीन को खरीदने के लिए कौन सी भुगतान शर्तें स्वीकार की जाती हैं?

A3: हम इस उत्पाद के लिए भुगतान की शर्तों के रूप में L/C (क्रेडिट का पत्र) और T/T (टेलीग्राफिक ट्रांसफर) को स्वीकार करते हैं।

Q4: आदेश देने के बाद मशीन देने में कितना समय लगता है?

A4: डिलीवरी का समय आम तौर पर 7 से 30 कार्य दिवसों के बीच होता है जब हम आपका भुगतान प्राप्त करते हैं।

Q5: HWASHI HS-HC-1-7 स्वचालित वायर शेल्फ वेल्डिंग मशीन को शिपमेंट के लिए कैसे पैक किया जाता है?

A5: सुरक्षित परिवहन सुनिश्चित करने के लिए मशीन को समुद्र के योग्य लकड़ी के पैकेज में पैक किया गया है।

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!